Precast and pre-stressed concrete is a major industry in which rubber tired gantry (RTG) cranes are utilized for heavy lifting applications. The mobile gantry crane solution allows a user to minimize the number of times they handle a product and removes any confusing load charts which need to be deciphered, resulting in a more safe and efficient means to move product. Precast and pre-stressed concrete can come in many different configurations depending on the intended end use and the engineer’s design, so Shuttlelift offers four different models of industrial mobile gantry cranes to make sure customers get a perfect fit for any job.

There are many different applications for precast and pre-stressed concrete and this blog series will break down a few of the main uses and how different style rubber tired gantry cranes can be used to accomplish the job at hand. The three-part series will include the following:

- Bridge Work

- Parking and Commercial Buildings

- Drainage

Bridge Work

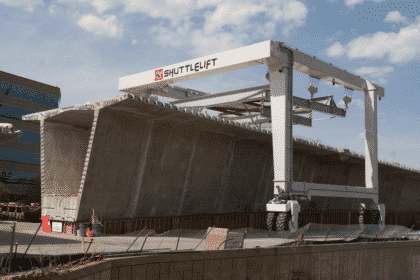

Infrastructure is key to any successful society and keeping roads and bridges safe for its users is usually a topic of importance. Bridges are mainly constructed of steel or precast concrete and since we are concentrating on concrete applications with this blog we will focus on that. Two of the main types of components used in precast bridge projects are a precast beam or girder sections and segmental pieces. Rubber tired gantry cranes can be used in multiple ways to handle these pieces, from stripping forms and loading trucks or barges for transport to offloading and placing segments at the job site.

Beams and Girders

Precast beams and girders just keep getting bigger and longer as engineering designs become more intricate and aesthetic. Depending on the overall length of the girder, and where the pick points are located, there are a few different ways a rubber tired gantry crane can be used to move this type of product.

When beams and girders are needed with extensive lengths, it becomes safer and more economical to handle these products with two rubber tired gantry cranes in tandem. The DB style mobile gantry cranes can be used in tandem with spreaders to bring each machine to a single point pick, but the SB (Single Beam) style mobile gantry cranes are ideal for tandem carry applications. The Shuttlelift SB cranes have a single hook and do not require spreaders to perform in tandem. This gives the customer full machine capacity under the hook and with less structure, the SB style cranes are more maneuverable around tight turns and spaces in your yard.

Two 50 U.S. ton capacity SB style cranes would give you a total of 100 U.S. ton capacity when used in tandem and are comparable, and most times less money, than a single 100 U.S. ton capacity DB style gantry crane with a needed spreader.

Segmental Systems

When stripping and moving precast segmental bridge pieces there are two main types of rubber tired gantry cranes that work best. The setup of your yard or job site, and whether you need the ability to traverse the load within the inside clear width of the gantry crane, will determine the best crane for your application.

The most common and popular way to move segmental precast pieces is with a DB style mobile gantry crane equipped with a dual-trolley system and custom spreader. If pick points on the segmental pieces remain constant the trolleys can be set to a fixed distance apart with two longitudinal spreaders. However, some projects can require segmental pieces of varying size and pick point configurations. In this case, the dual-trolley system can be provided with variable spacing or a custom spreader assembly with sliding pick points can be provided to ensure a customer can make all their picks with one rubber tired gantry crane.

If the load does not need to be traversed within the inside clear width of the crane, and the mobile gantry crane will be used strictly as a pick-and-carry piece of equipment, the Shuttlelift SL series gantry crane is an excellent fit. The SL series cranes are used throughout the segmental bridge industry for storage and loading of products as well as on job site placing the pieces.